A new strategy to improve the stem sealing[R]

A graphite stem packing is composed ususally by dieformed flexible graphite ringsand die-formed braided packing rings in different shape and combinations

Test bench development for Rapid Gas Decompression evaluation of valve elastomer seals[R]

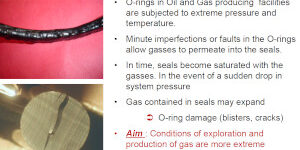

• O-rings in Oil and Gas producing facilities are subjected to extreme pressure andtemperature.• Minute imperfections or faults in the O-rings allow gasses to permeate into the seals.• In time, …

SEMI-DYNAMIC METAL SEALING Base theory and examples of valve applications

Common use of metal seals in the industry

Semi-dynamic sealing applications

Definition

Specificities on the assembly design

2 examples:

Quarter-turn metal stem sealing

Shut-off sealing for Triple Offset Butterfly Valves

Flexible Graphite Gaskets for Hydrogen Applications

Hydrogen production, properties, and use

Hydrogen sealing: Difficulties and solutions

Optimum graphite gaskets for hydrogen sealing

Additive Manufacturing: Re-shaping the Oil & Gas industry[R]

Case Study: Re-design, printing and testing of butterfly valve disc.

Ball valves for extreme high temperature service: design and coating validation by means of bench sessions and performance tests[R]

Higher and higher performances required in the Oil&Gas field High temperature, thermal cycles, high pressures Importance of durability and effectiveness